Shurflo Liquid Pump Schematic – Parts Supply for Installations

Incorrect installation of liquid pumping devices can significantly reduce their efficiency by up to 30%. It’s essential to understand the operation of the Shurflo Water Pump schematic for maximum efficiency and durability. Each component within the diagram plays a crucial role in the operation of the Pump. This article examines the significance of understanding these Shurflo 8000 parts, using the diagram to illustrate their configuration and how they operate in unison.

Installation Parts Supply is your primary source for every Shurflo Pump component essential for assembly and servicing. Learning via the Shurflo Water Pump parts diagram enables users to expertly handle installation and upkeep. This knowledge aids in making informed choices for the efficient and secure functioning of their Water Pump units.

Grasping Shurflo Pump Systems

Shurflo Pump systems are at the nexus of ingenuity and utility, meeting the demands of various uses. This segment aims to give a detailed look into Shurflo Water Pump models, their particular applications, and the merits of choosing these Pump systems. They are famed for their advanced technology and effectiveness.

Overview of Shurflo Pump Models

Shurflo’s line-up includes pumps like the membrane and horticultural series, designed for multiple needs. The membrane models are acclaimed for their robust build and liquid transfer efficiency. Models like the 2088-343-135 and 2088-343-500 offer robust performance with remarkable flow and pressure specifications.

The agricultural series, conversely, is built for effective fluid transport in agricultural settings.

Applications of Shurflo Pumps

The adaptability of Shurflo Pump systems allows their use in a variety of settings. They are typically utilized for:

- Farming: Delivers options for watering and nutrient application.

- RVs: Ensures a consistent water supply with regulated pressure settings.

- Domestic: Ideal for yard upkeep and home Water Pump installations.

This adaptability permits these devices to integrate smoothly into various setups, showing their adaptable nature.

Advantages of Employing Shurflo Pump Systems

Choosing Shurflo Pump systems brings several advantages. Their ability to self-prime eliminates the need of manual operation startup. They also offer corrosion resistance, ensuring longevity in harsh environments. Readily available Shurflo membrane Pump parts simplifies upkeep, extending operational longevity while minimizing downtime. Additional merits of Shurflo Pump systems comprise:

- Consistent operation with customizable pressure settings.

- Effortless assembly with catalog guidance.

- Multiple fitting types ensuring compatibility with current systems.

With these attributes, Shurflo Pumps promise consistent performance and dependability. They maintain uninterrupted operation, providing users with confidence in their functionality.

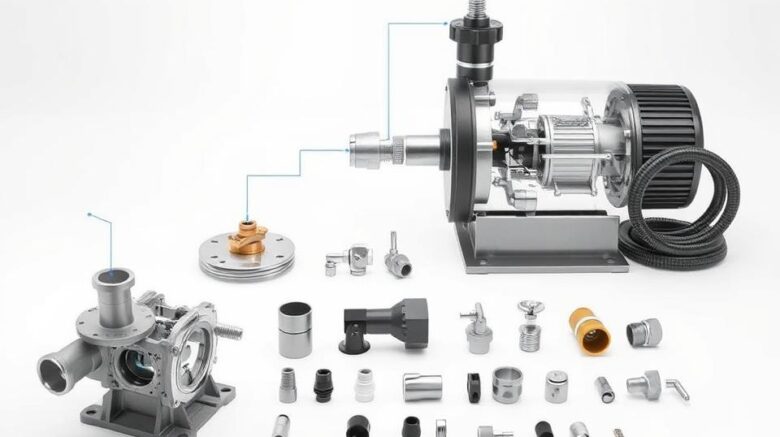

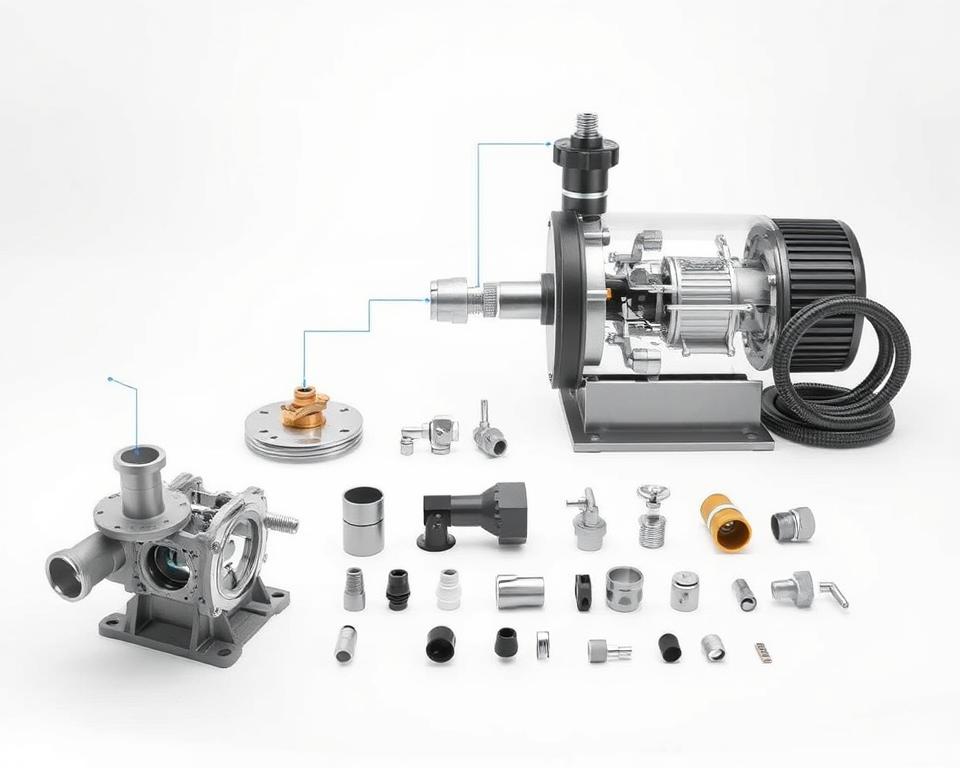

The Shurflo Water Pump Schematic and Its Significance

The Shurflo Pump schematic is critical for comprehending its elements and operations. By learning about the Shurflo Pump schematic, users can construct, troubleshoot, and maintain efficiency. This schematic is vital for identifying the necessary Shurflo Pump parts. Accurate assembly guided by the diagram guarantees peak performance.

Essential Elements in the Diagram

The Shurflo Water Pump schematic showcases essential components vital for the pump’s functionality:

- Engine: The motor, the heart of the Pump, powers the rotor, delivering flow rates between 41 and 168 GPM.

- Diaphragm: Helps sustain consistent flow and pressure.

- Check Valves: Key to stopping reverse circulation, these valves ensure that fluid flows in the right direction.

- Housing: With a maximum pressure of 200 PSI, the housing secures longevity.

Understanding the Shurflo Pump Diagram

To read the Shurflo Pump diagram, one must pay attention to particular icons and labels:

- Understand the configuration of elements illustrated.

- Determine the movement direction marked by arrows.

- Check notes for details like wire sizes and mounting options.

Familiarity with this diagram is essential for proper assembly, maintenance, and identifying key components.

Setting Up Shurflo Water Pumps

Installing a Shurflo Water Pump can enhance the functionality of any liquid system. Understanding the required procedures and parts is crucial for a good installation. This tutorial details essential procedures and necessary equipment for a triumphant installation.

Step-by-Step Guide to Installing a Shurflo Pump

- First, assemble all equipment for shurflo pump installation. Verify that you have a suitable screwdriver, wrench, and 50-mesh strainer.

- Attach the 50-mesh strainer to the inlet of the Pump. It’s best to use a flexible hose when linking the inlet to minimize strain on fittings.

- Apply a 1/2” to 3/8” barb splicer for connecting tubing securely. To avoid leaks, opt for durable tubing equipped with Oetiker clamps.

- Ensure the Pump is linked to a correctly grounded outlet. A professional electrician should handle this to meet regional standards.

- Charge the accumulator tank with 50 PSI of clean air or nitrogen. This is vital for achieving ideal pressure levels.

- Place a SHURflo 65 psi water pressure reducer valve at the inlet to maintain appropriate pressure conditions.

- Wrap up the setup by connecting all components. Don’t exceed the motor’s amperage rating; thermal breakers offer extra safety.

- Test the system and check the pressure switch’s functionality.

Tools and Parts Required for Installation

| Item | Description |

|---|---|

| 50-mesh filter | Filters debris at the pump’s inlet to ensure optimal performance. |

| Bendable hose | Preferred for inlet use, minimizing pressure on connectors. |

| Barb splicer | Provides a secure 1/2” to 3/8” tubing linkage. |

| Accumulator tank | Inflated to 50 PSI to uphold system pressure. |

| Pressure switch | Manages Pump function according to pressure needs. |

| Electrical supplies | Essential for proper electrical hookup, following local codes. |

| 65 psi SHURflo valve | Ensures steady pressure by reducing the water pressure at the inlet. |

Diagnosing Frequent Problems in Shurflo Pumps

Understanding how to remedy frequent problems in Shurflo Pump systems enhances performance. This part offers a problem-solving manual. It guides users through resolving typical malfunctions to maintain uninterrupted function. Issues such as pump functionality, water flow, and noise are tackled with practical solutions.

Common Problems and Their Solutions

Various conditions may result in malfunctions with Shurflo Pumps. Below are key problems and their solutions:

- Pump runs but no water flow: Check the freshwater tank level, inspect the water line for blockages or damage, ensure proper priming, and verify the water pump’s functionality.

- Pump fails to start post-winterization: Examine winterization methods, ascertain all valves are operable, inspect electrical setups, and search for signs of damage.

- Pump intermittently starting and stopping: Examine the system for leakages, purge air pockets, set correct pressure levels, and confirm Pump operation.

- Noisy pump: Examine connections for looseness, install supportive padding, shield pipes, and confirm accurate installation.

Shurflo Pump Troubleshooting Guide

A complete Shurflo Pump troubleshooting guide helps rapidly pinpoint problems. The following table summarizes typical issues and corrective actions:

| Frequent Problem | Potential Causes | Solutions |

|---|---|---|

| Operation without liquid movement | Low freshwater tank, blockages, improper priming | Check tank level, inspect water line, verify pump function |

| Pump won’t turn on | Improper winterization, closed valves, electrical issues | Review winterization, open valves, check connections |

| Pump cycles on and off | Faulty seals, air pockets, pressure misconfigurations | Inspect for leaks, remove air, adjust pressure settings |

| Noisy pump | Loose connections, inadequate installation | Tighten connections, add padding, insulate pipes |

Grasping the shurflo pump exploded view enables users to locate malfunctioning components is key to proper troubleshooting. Observing these steps guarantees proper maintenance and dependable functioning.

In Summary

Understanding the Shurflo Water Pump schematic is vital for achieving maximum Pump efficiency.

Utilized in various fields like RVs and agricultural spraying, efficient setup is crucial for dependable outcomes.

Familiarity with the diagram’s elements allows for efficient installation and sustained maintenance.

Installation Parts Supply stands as the premier source for all essential Shurflo Pump components and support, delivering extensive service along with vital instruments and elements. Such support guarantees proper assembly. By adhering to proper plumbing, wiring, and upkeep of parts like the strainer, the operational life and efficiency of the Pumps are boosted.

This guide equips users with the expertise required to maximize Shurflo Pump efficiency. Employing Shurflo Pump technology alongside these installation recommendations readies users to overcome any obstacles confidently.